Before cars become brochures, social media posts, or Nürburgring lap times, they live here.

Not racetracks in the traditional sense, but engineering instruments used for OEM vehicle testing and calibration validation. These environments exist to remove excuses, expose assumptions, and confirm that performance, stability, and control systems behave exactly as intended.

These tracks answer very unromantic questions.

Does the vehicle remain stable at 250 km/h without steering input?

Does stability control intervene at the correct point on the µ-slip curve?

Does the powertrain survive hours at the limiter without thermal or mechanical compromise?

This is where automotive calibration becomes accountable.

Ehra-Lessien (Germany)

Hidden near Wolfsburg, Ehra-Lessien is Volkswagen Group’s high-speed validation facility. Its 5.6-mile straight is used for sustained maximum velocity testing under controlled conditions.

Historically, Ehra-Lessien was not exclusive. During the 1970s through to the early 1990s, multiple German OEMs, including Mercedes-Benz, conducted controlled testing here. At the time, Germany had very few facilities capable of sustained high-speed, steady-state validation, and shared infrastructure was normal.

Today access is tightly restricted. The focus is not peak speed figures, but repeatability, stability, cooling margin, tyre growth, alignment behaviour, and structural confidence at extreme velocity.

Ehra-Lessien is not about excitement.

It is about certainty.

MIRA Proving Ground (UK)

MIRA is not a single test discipline. It is a systems validation environment, designed so wet handling, dry handling, ride, NVH, durability, and high-speed testing collide rather than exist in isolation.

During my time working in the UK, this was where theoretical models stopped being tolerated. Assumptions were driven over, soaked, shaken, and repeated until they either survived or were removed from the design.

The Belgian Pavé is not designed to break cars. It exists to compress years of structural fatigue into weeks, exposing optimism in bushings, mountings, heat shielding, and fastener retention.

MIRA answers a simple question: does the vehicle still behave correctly after it has been punished?

IDIADA Proving Ground (Spain)

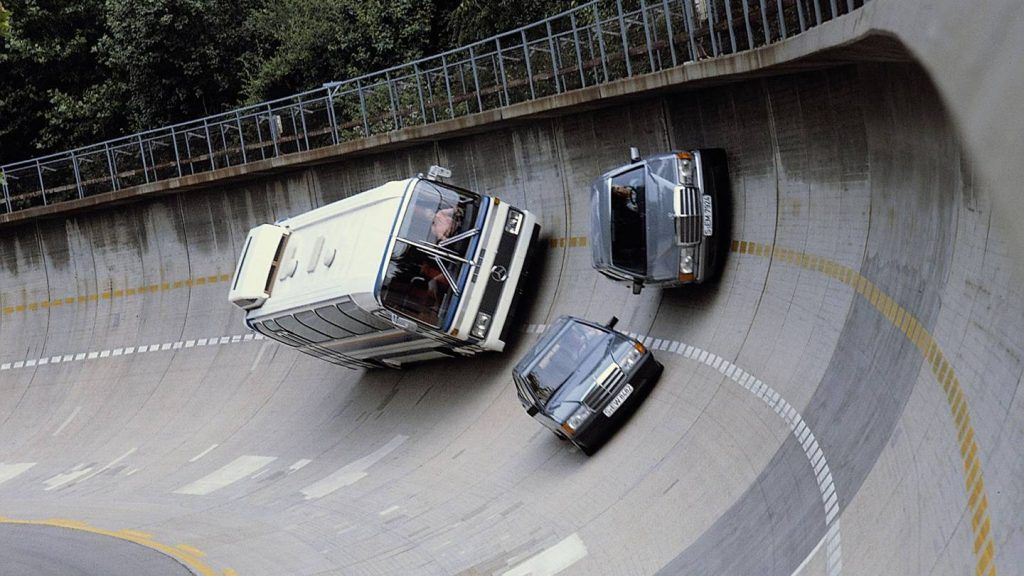

IDIADA is where physics is allowed to speak freely. During Mercedes hot trips, I was in the vehicle while high-speed stability validation was carried out at 250 km/h with no steering input on the banked high-speed circuit.

That exercise was intentionally uneventful. Hands off the wheel, steady-state running, and nowhere for geometry, alignment, tyre growth, aero balance, or stability thresholds to hide.

Separate to this, vehicle handling and control behaviour were developed and validated on IDIADA’s handling circuits. Here, transient response, intervention thresholds, and system cooperation were evaluated under repeatable, controllable conditions.

Using dSPACE rapid prototyping systems on the handling track, ESP logic was modified, evaluated, and iterated in real time. Cause and effect were immediate, measurable, and difficult to argue with.

Many of those control strategies now exist, under licence, across multiple OEM platforms.

Leipzig Porsche Test Track (Germany)

The Leipzig test track compresses global road archetypes into a single, repeatable loop. Surface transitions, corner radii, elevation changes, and transient events are deliberately stacked.

This forces calibration to remain robust across conflicting inputs. Throttle, steering, brake, and stability systems are evaluated not for outright performance, but for consistency and predictability.

If a calibration only works when conditions are ideal, Leipzig exposes it quickly.

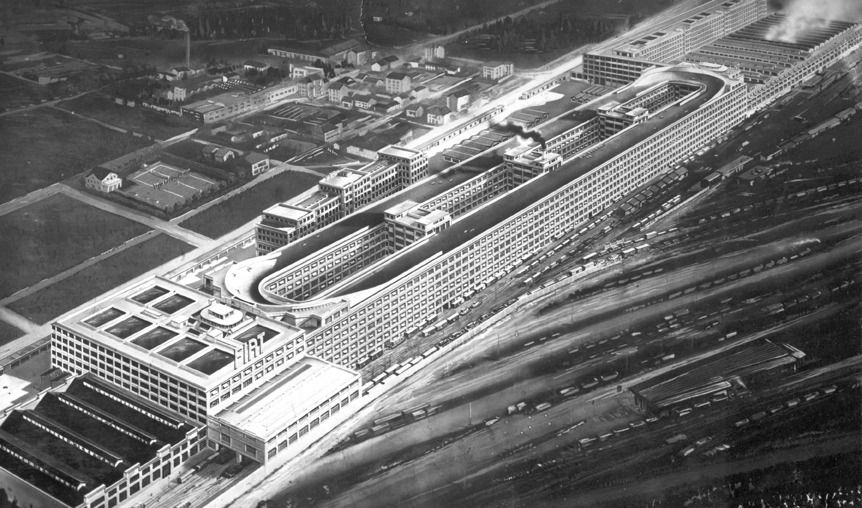

Lingotto Test Track (Italy)

Lingotto belongs to an era when the boundary between development and production was, by modern standards, somewhat optimistic.

Vehicles were driven from the production line to the rooftop track for final functional checks, implying that calibration, durability, and system behaviour were still being observed at a point where engineers today would expect them to be closed.

That approach reflects the tools and processes of its time, but it also explains why Lingotto now exists as an architectural curiosity rather than an engineering template.

Final validation on the roof is an interesting solution. Finishing development before production is a better one.

Lingotto is a museum piece, and that is entirely appropriate. Production vehicles should not require post-production validation. If a car still needs engineering attention after it leaves the factory, the development process has already failed.

Nardò Technical Centre (Italy)

Nardò is a durability amplifier. Its constant-radius high-speed loop allows engines, gearboxes, differentials, tyres, and lubrication systems to be held at sustained load for hours.

This removes the relief that acceleration tests provide. Oil temperature, coolant stability, aero balance, and component wear are all forced into steady-state reality.

Nardò answers the question: what happens after the first hour?

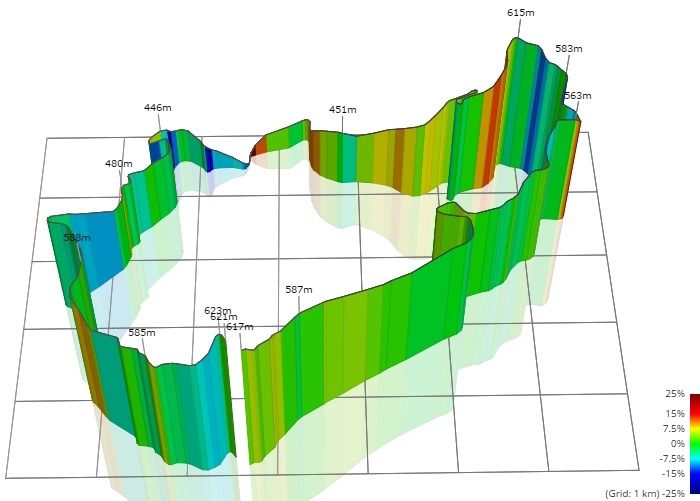

Nürburgring – The Green Hell

The Nürburgring is not a handling track, a durability track, or a high-speed circuit. It is all of them, continuously, with no recovery time and no tolerance for mistakes.

Elevation change, camber variation, surface inconsistency, braking asymmetry, and transient load shifts are stacked relentlessly. Loads arrive early, linger longer than expected, and combine in ways simulation and proving grounds deliberately avoid.

This is what makes it so effective, and so dangerous. Cooling strategies that appear robust elsewhere quietly unravel. Damping compromises stop being theoretical. Torque management, stability logic, brake thermal capacity, and drivetrain protection are forced to cooperate under conditions that punish hesitation and expose optimism.

The Nürburgring carries real consequence. There are no terrain warnings here. Errors are not politely logged. They are amplified by speed and proximity.

The Nürburgring does not break cars.

It removes lies.

Why This Matters at AutoUpgrades

This OEM-level approach to vehicle calibration underpins the work we do at AutoUpgrades.

We focus on behaviour under load, predictability at the limit, and correct system interaction. The same principles used in OEM development apply directly to high-quality ECU calibration.

This is why our work on platforms like Mercedes-Benz ECU tuning prioritises refinement, stability, and durability over peak numbers.

Data first.

Ego last.

Physics always wins.